Carbide 3D Tooling Guide

Tooling Guide

| Cutter | Shank | Flutes | OAL | LOC | CD | Type | Link |

|---|---|---|---|---|---|---|---|

| 101 | .125” | 2 | 1.5” | 0.500” | .125” | Ball Nose | Buy |

| 102 | .125” | 2 | 1.5” | 0.500” | .125” | Square End | Buy |

| 111 | .125” | 2 | 1.5” | 0.250” | .063” | Ball Nose | Buy |

| 112 | .125” | 2 | 1.5” | 0.250” | .063” | Square End | Buy |

| 121 | .125” | 2 | 1.5” | 0.063” | .032” | Ball Nose | Buy |

| 122 | .125” | 2 | 1.5” | 0.063” | .032” | Square End | Buy |

| 201 | .250” | 3 | 2.5” | 0.750” | .250” | Square End | Buy |

| 202 | .250” | 3 | 2.5” | 0.750” | .250” | Ball Nose | Buy |

| 301 | .250” | 2 | 2.5” | 0.250” | .500” | V-Bit | Buy |

| 302 | .250” | 2 | 2.0” | 0.4357” | .500” | V-Bit | Buy |

See our full range of cutter options here: https://shop.carbide3d.com/collections/cutters

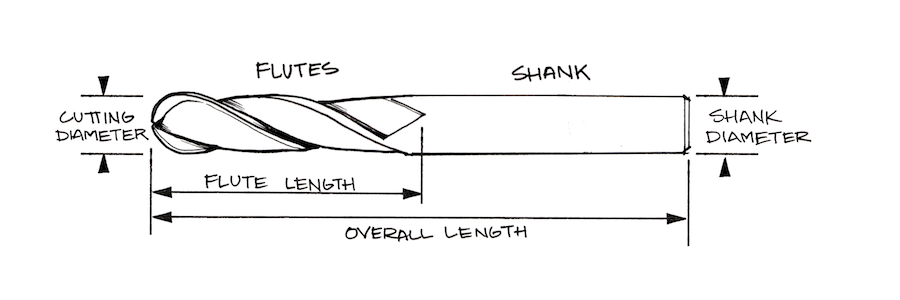

Anatomy of an Endmill

Shank: The diameter of the non-cutting end of the cutter. The shank diameter determines what size collet should be used to hold the cutter in the spindle.

Overall Length (OAL): The total length of the cutter. This can be determined by measuring from one end of the cutter to the other. Tip to Tip.

Length of Cut (LOC): The total length of the cutting surface of the cutter. If this dimension is less than the dimension of the shank, the LOC is effectively how far down the cutter can plunge (total) into the material.

Flutes: The number of cutting surfaces found on the cutter. For example, a 2 flute cutter has two cutting edges, a 3 flute cutter has 3 cutting edges.

Cutting Diameter: The diameter of the cutting area of the end mill. Note, this can be different from the shank size of the cutter. This is also called ‘Cutting Edge Diameter’

Choosing the Right Tool

End Mills

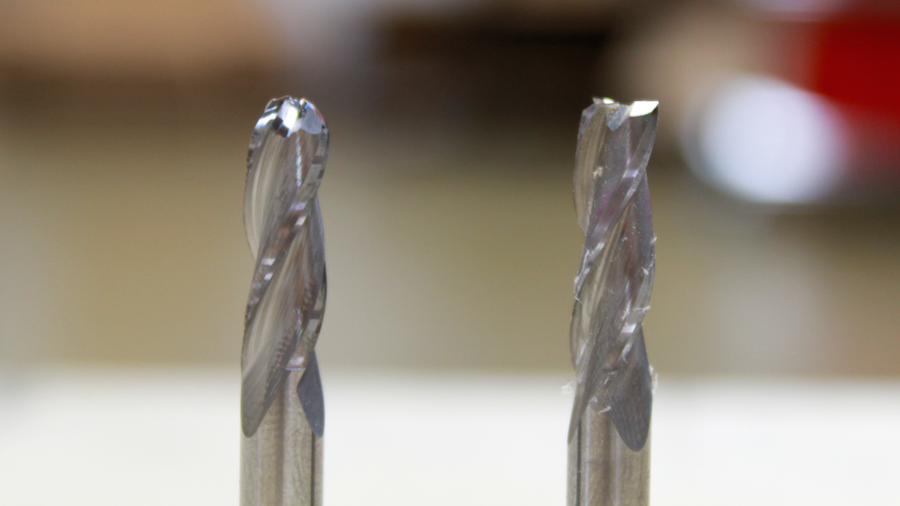

Endmills generally come in 2 varieties: Square End Mills and Ballnose end mills.

Aside from the shape of the endmill, the tip geometry also varies between types, determining the way the chips are ejected and effecting the smoothness of the finish.

Up-Cut

Up-cut end mills ‘pull’ the chips UP and out of the slot. These tend to leave a smooth finish on the bottom of the material.

Down-Cut

Down-Cut end mills ‘push’ the chips down into the slot. These tend to leave a smooth finish on the top of the material.

Compression

Compression cut endmills have a mixture of up-cut and down-cut flutes, creating a smooth finish on the top and bottom of the material.

Note: The cutters we stock in the store are all of the up-cut variety. If you’re interested in another variation, please let us know by sending an email to sales@carbide3d.com

Scallops:

Square end mills will cut a smooth flat bottom surface, while Ballnose End mills will not cut a flat bottom surface, instead they will leave scallops.

Contours

Ball nose end mills are known to be used for contoured or organic shapes. They do a nice job of getting in the nooks and crannies of contours without disturbing the surrounding material.

Square End mills are commonly used for 2D and 2.5D parts, where flat bottoms and vertical walls define the design.

V-Cutter (engraving)

A V shaped cutter is used to create V-carving designs. Because of how V-carving toolpaths are generated, you can create very fine and very wide details with the same cutter. It’s important to remember that the flatness of your material will make a difference with the results when using a V-cutter.